in cooperation with

|

| ... will be updated weekly... |

👉SLQ Consultants: Contact our experts HERE

The Medical Device Regulation (MDR)

The Medical

Device Regulation defines a medical device as “any instrument,

apparatus, appliance, software, implant, reagent, material or other article

intended by the manufacturer to be used, alone or in combination, for human

beings for one or more of the following specific medical purposes:

- diagnosis, prevention, monitoring, prediction, prognosis, treatment or alleviation of disease,

- diagnosis, monitoring, treatment, alleviation of, or compensation for, an injury or disability,

- investigation, replacement or modification of the anatomy or of a physiological or pathological process or state,

- providing information by means of in vitro examination of specimens derived from the human body, including organ, blood and tissue donations.

and which does

not achieve its principal intended action by pharmacological, immunological or

metabolic means, in or on the human body, but which may be assisted in its

function by such means. MDR also includes devices for the control or support of

conception; products specifically intended for the cleaning, disinfection or

sterilization […] Software shall also be deemed to be an active device.

Please click: You will find the document here.

Regulatory is still in the transition period. For the time being the Medical Device Directives with their national laws are still in place.

Standards and norms help you to be compliant with the medical device regulations (MDR). The most important standard for a medical device company is standard ISO 13485:

About ISO 13485

ISO 13485 process approach

treats the QMS as a set of interrelated processes covering not only the

manufacture of a product or provision of a service, but also management

processes and support processes. A "process" is something that

transforms a collection of inputs into outputs. Inputs consist of everything

needed to accomplish this transformation. For manufacturing a device these this

might include such things as raw materials, manufacturing supplies, work

benches, cleaning materials, tools, and equipment, the building, people,

written instructions, assembly drawings, comparison samples, and workmanship

standards, working instructions, test specifications. The output of the

process, that is the transformation of these inputs, produces the finished

part, records about what was done by who, and information about how the

transformation was accomplished, such as time to complete or production yield.

Unwanted outputs might include scrap parts and wasted material. For

non-manufacturing processes, for example document control, inputs might include

document control procedure, change request, people, equipment (copy machine,

computer, scanner), document control center, and the outputs would include

controlled documents, controlled copies, and process statistics. As you can see

from even just these two examples, the output of one process, i.e. document

control, is the input to other processes, such as manufacturing.

Of course there are more standards and norms applying to the design and the development of your medical device. The picture below should guide you through this jungle of norms and standards.

Of course there are more standards and norms applying to the design and the development of your medical device. The picture below should guide you through this jungle of norms and standards.

The lifecycle of a medical device

The lifecycle of a medical device can be divided in seven main stages "from birth to death"

During the different stages, various stakeholders are involved in realizing, distributing, and using a medical device.

The importance of a regulatory strategy

Planning regulatory submission activities from the very first beginning is essential for a successful approval of your medical device. Following this roadmap may be of assistance. Visualize your regulatory strategy and realize regulatory as a strategic planning game: There will be only one winner at the end of the game. It is YOU and your company. Use regulatory as helpful tool and it will guide you through your development process...

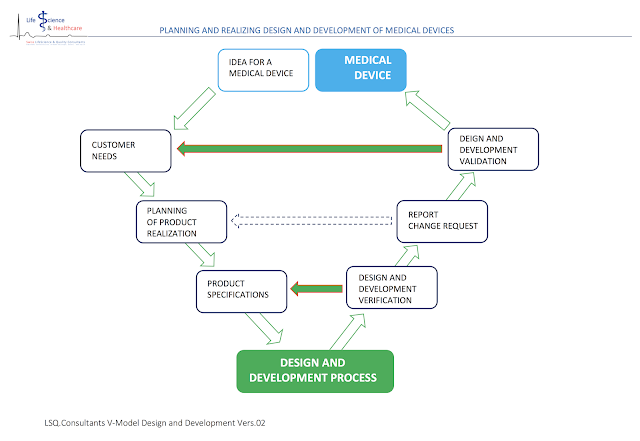

Planning and realizing design and development of medical devices

Every manufacturer of medical devices must document and record all design and development results in the form of specifications, manufacturing procedures, technical drawings and/or laboratory journals.

The results must be

available and be prepared in such a way that they can be verified against the

defined design and development requirements. All results must be released and

approved before the verification. The

manufacturer shall provide information for the procurement, production and service

activities resulting from the development results and establishing acceptance

criteria for the product.

1. THE IDEA FOR A MEDICAL DEVICE. Customer requirements and user needs:

At the very first beginning of your design and development work, listen to your customers needs: This can be a person (surgeon, patient, other user) but this can also be an analysis of the needs of the market.

Record and file all your findings. These findings are the very first specifications of your device. Bring them to paper and try to translate the more descriptive user needs into technical specifications of your device. Start a table and fill in [a] user needs, [b] the translation into technical specifications, [c] applying standards and norms, and [d] possible risks you can identify with the use of your medical device. Risks for the patient AND the user.

2. PRODUCT REALIZATION. Design and development planning:

In this chapter, you will learn more about the different design and

development phases and how they interact and build on one another. This chapter

is very important for you as developer and manufacturer, since designing a

medical device is a sequential process with given and defined design and

development phases that must be followed without any gaps.

A medical device

company that plans its product realization must plan and control the design and

development of (the) product. […] documents shall be maintained and updated as

the design and development progresses [ISO 13485:2016,

7.3.2]. The company must coordinate the different groups and experts that are

involved in this process.

Ask yourself these important questions:

Which processes (internal and external/outsourced) are

required for the design and development of compliant products? Which activities

and tasks must be performed to ensure those processes? What are the key

positions to be occupied? What other positions are required? What are the responsibilities

and authorities for the positions identified? Which knowledge, skills and

abilities are demanded for those roles, tasks and activities?

To answer these

questions, build up your processes in simple process maps. This helps you to

get an overview and visualization of all relevant processes and how they

correlate to each other, showing important interfaces and critical points

between the sequence of processes.

>> ISO 13485:2016 and MDR: Design and Development Documentation Requirements <<  |

| Please check this LINK: Product Realization - Documentation Requirements |

Keine Kommentare:

Kommentar veröffentlichen